A CNC EPS cutting machine is a specialized piece of equipment designed to cut expanded polystyrene (EPS) foam with high precision. EPS foam, commonly known as Styrofoam, is widely used in various industries for its lightweight, insulating properties, and ease of shaping. CNC (Computer Numerical Control) technology automates the cutting process, allowing for intricate designs and consistent quality. This article explores the components, working principles, benefits, and applications of CNC EPS cutting machines.

Understanding CNC EPS Cutting Machines

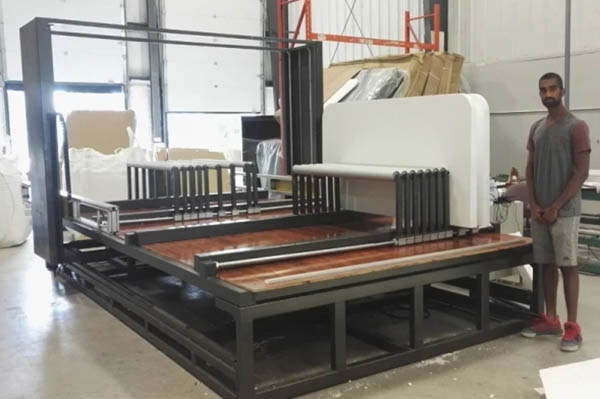

A CNC EPS cutting machine is essentially a computer-controlled device that uses a heated wire, blade, or router bit to cut through EPS foam. These machines can create complex shapes, designs, and patterns with a high degree of accuracy. The “CNC” aspect of the machine refers to its ability to be programmed with specific cutting paths and parameters, ensuring each cut is identical to the last.

Key Components of a CNC EPS Cutting Machine

- Cutting Head: The cutting head of a CNC EPS machine can vary depending on the model and intended use. The most common cutting heads use hot wires, which are heated to a specific temperature to melt through the EPS foam. Other machines may use blades or router bits for different types of cuts.

- Worktable: The worktable is the flat surface where the EPS foam block is placed. It typically moves along the X and Y axes, allowing the foam to be positioned correctly for cutting. Some advanced machines may also have a rotating table for more complex cuts.

- Control Panel: The control panel is where the operator inputs the cutting parameters and designs. It is connected to a computer that runs CAD (Computer-Aided Design) software, which generates the tool paths for the cutting head.

- Frame and Gantry: The frame and gantry provide the structural support for the machine. The gantry moves along the Z-axis, allowing the cutting head to move up and down, while the frame keeps everything stable and aligned.

- Computer System: The computer system is integral to CNC operations. It stores and processes the CAD files, translates them into machine code, and sends the commands to the cutting head and work table.

How Does a CNC EPS Cutting Machine Work?

The operation of a CNC EPS cutting machine involves several steps, all of which are automated through computer programming:

- Design Creation: The process begins with creating a design using CAD software. The design can be a simple 2D shape or a complex 3D model, depending on the machine’s capabilities.

- Conversion to Machine Code: Once the design is complete, the CAD file is converted into machine code (G-code). This code provides detailed instructions to the CNC machine on how to move the cutting head and work table to achieve the desired shape.

- Setup: The EPS foam block is placed on the worktable and secured. The operator then loads the machine code into the CNC system and sets any necessary parameters, such as cutting speed, wire temperature, or bit rotation speed.

- Cutting Process: The machine begins the cutting process by moving the cutting head along the programmed path. The hot wire, blade, or router bit melts or cuts through the EPS foam, following the precise instructions from the machine code.

- Completion: Once the cutting is complete, the machine stops, and the operator removes the finished piece. The CNC system can then be reprogrammed for the next cut, ensuring consistency and efficiency for mass production.

Benefits of Using a CNC EPS Cutting Machine

- Precision and Accuracy: CNC EPS cutting machines can achieve highly precise cuts with minimal waste. This accuracy is particularly beneficial for industries that require detailed patterns or shapes, such as packaging, construction, and signage.

- Efficiency: Automation significantly reduces the time required to produce each piece, making CNC machines ideal for high-volume production. The repeatability of CNC cutting also ensures uniformity across all products.

- Versatility: These machines can handle a wide range of cutting tasks, from simple straight cuts to intricate 3D shapes. This versatility makes them suitable for various applications, from architectural modeling to custom packaging.

- Cost-Effective: While the initial investment in a CNC EPS cutting machine may be high, the long-term savings in labor costs and material waste make it a cost-effective solution for many businesses.

- Safety: The automation of cutting processes reduces the need for manual intervention, minimizing the risk of accidents and injuries. Additionally, the use of CNC technology allows for the use of safety protocols and protective features that further enhance operator safety.

Applications of CNC EPS Cutting Machines

CNC EPS cutting machines are used across various industries for different applications:

- Construction: In the construction industry, EPS foam is often used for insulation, lightweight concrete forms, and architectural moldings. CNC machines can cut these materials to precise specifications, ensuring a perfect fit on the job site.

- Packaging: EPS foam is an excellent material for packaging due to its shock-absorbing properties. CNC EPS cutting machines can create custom-shaped packaging inserts that protect products during shipping.

- Signage: EPS foam is a popular choice for creating signs and displays due to its lightweight and easy-to-paint surface. CNC machines can cut intricate letters and designs that are then finished with paint or other coatings.

- Modeling and Prototyping: Architects and engineers often use EPS foam to create scale models of buildings and other structures. CNC cutting allows for the creation of detailed and accurate models quickly and efficiently.

- Arts and Crafts: Artists and designers use EPS foam for sculptures and custom projects. CNC machines provide the precision needed to bring their creative visions to life.

Conclusion

A CNC EPS cutting machine is a powerful tool that combines the precision of CNC technology with the versatility of EPS foam cutting. It offers numerous benefits, including high accuracy, efficiency, and safety, making it an invaluable asset in industries ranging from construction to packaging. Understanding how these machines work and their various applications can help businesses and individuals choose the right tool for their specific needs. Whether you’re producing custom packaging, architectural models, or intricate signs, a CNC EPS cutting machine can help you achieve your goals with ease and precision.

Post time: 08-30-2024