Expanded Polystyrene (EPS) is a versatile material used in various industries, from packaging and insulation to construction and automotive applications. EPS shape molding machines are the primary equipment used to form EPS into custom shapes, catering to specific needs across these sectors. With automation becoming a standard in manufacturing processes, automatic EPS shape molding machines have gained popularity for their efficiency, precision, and cost-effectiveness. In this article, we will explore the different types of automatic EPS shape molding machines and their unique features.

1. Standard Automatic EPS Shape Molding Machines

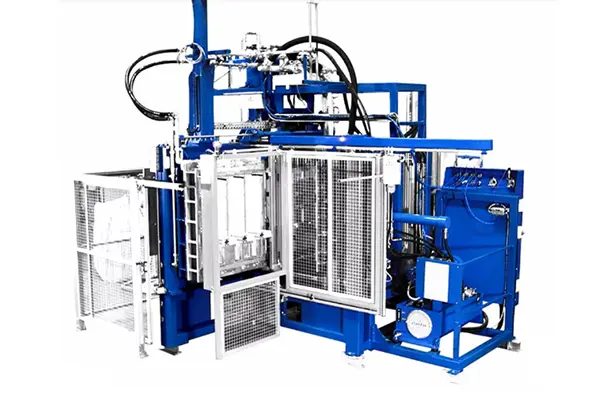

Standard automatic EPS shape molding machines are the most commonly used type in the industry. These machines are designed to mold EPS beads into a wide range of shapes, such as packaging materials, insulation boards, and protective foam products. The key feature of these machines is their ability to perform continuous, automated production with minimal human intervention.

- Basic Operation: The EPS beads are injected into a pre-heated mold cavity, where steam is applied to expand the beads. The machine controls the steam, pressure, and cooling processes to shape the EPS material into the desired form.

- Customizable Molds: Standard automatic machines can be equipped with different mold configurations, allowing manufacturers to produce a variety of shapes and sizes. This versatility makes them suitable for mass production of standard EPS products like packaging blocks or construction panels.

- Efficiency: The machine’s automation significantly reduces production time and labor costs. With advanced control systems, the machine can optimize the molding process, ensuring consistent product quality.

2. Vertical Automatic EPS Shape Molding Machines

Vertical automatic EPS shape molding machines are designed with a vertical mold-opening structure. These machines are ideal for producing large and complex shapes, such as building insulation panels or decorative architectural components.

- Space-Saving Design: The vertical layout of the machine reduces the footprint compared to horizontal machines, making it ideal for factories with limited space. The vertical mold-opening system also makes it easier to load and unload large molds, increasing production efficiency.

- High Precision: These machines are equipped with precise control systems that regulate steam, pressure, and cooling to ensure high-quality molding. The vertical orientation provides even steam distribution, which is essential for molding large, complex shapes.

- Versatility: Vertical machines are versatile and can handle both small and large production runs. They are particularly well-suited for producing custom EPS shapes used in construction, like insulated concrete forms (ICFs) or lightweight building blocks.

3. Vacuum Automatic EPS Shape Molding Machines

Vacuum automatic EPS shape molding machines incorporate vacuum technology to enhance the molding process. These machines offer superior performance in terms of molding speed, energy efficiency, and product quality, making them ideal for high-end and precision EPS products.

- Faster Molding Cycles: The vacuum system accelerates the steam condensation process, reducing the cooling time required during the molding cycle. This results in faster production cycles and higher output, making vacuum machines suitable for large-scale manufacturing.

- Energy Efficiency: By using a vacuum to remove air from the mold cavity, these machines require less steam to expand the EPS beads. This not only reduces energy consumption but also minimizes waste, making the process more eco-friendly.

- Improved Product Quality: The vacuum ensures that the EPS beads fill the mold cavity evenly and tightly, eliminating air pockets and ensuring uniform density. This leads to higher-quality, more durable EPS products with a smooth surface finish, which is crucial for applications like protective packaging and decorative components.

4. Block Molding Machines

Block molding machines are a specific type of automatic EPS shape molding machine designed to produce large blocks of EPS that can be further processed into smaller components. These blocks are often used for insulation, construction materials, and large packaging solutions.

- High Output: Block molding machines can produce large volumes of EPS blocks in a single cycle, making them ideal for manufacturers that require bulk quantities of material for downstream processing.

- Customizable Sizes: The machines are capable of producing blocks in a range of sizes and densities, depending on the specific application. This makes them highly versatile for industries like construction, where different insulation thicknesses are required.

- Post-Processing: Once the EPS blocks are produced, they can be cut, shaped, or laminated to create custom products. This flexibility allows manufacturers to produce EPS components with precise dimensions for construction or packaging.

5. 3D Automatic EPS Shape Molding Machines

3D automatic EPS shape molding machines represent the latest technological advancement in EPS molding. These machines are capable of creating complex, three-dimensional shapes that traditional molding machines may struggle to produce.

- Advanced Precision: Using computer-aided design (CAD) software, 3D automatic molding machines can produce highly detailed and intricate shapes. These machines are commonly used for custom packaging solutions, such as protective foam inserts for electronics or industrial equipment.

- Customization: With the ability to create complex, unique shapes, 3D molding machines are ideal for industries that require tailored solutions. The automotive, aerospace, and electronics industries frequently use these machines to create precise, lightweight protective components.

- Innovation: As technology evolves, the demand for more intricate EPS designs continues to grow. 3D molding machines allow manufacturers to meet these demands by offering customized solutions that improve product protection and reduce waste.

Conclusion

Automatic EPS shape molding machines come in various types, each designed to meet the specific needs of different industries. Standard automatic machines are ideal for mass production of packaging and insulation materials, while vertical machines handle large and complex shapes. Vacuum molding machines provide superior product quality and energy efficiency, while block molding machines excel in producing bulk EPS blocks. Finally, 3D molding machines are at the forefront of technological innovation, enabling the production of complex, custom shapes.

As industries continue to demand lightweight, durable, and versatile materials, EPS-shape molding machines will play a crucial role in meeting these needs. The future of EPS manufacturing lies in the continued development and adoption of automated, high-precision machinery that can deliver both quality and efficiency.

Post time: 09-21-2024