Before starting this topic, let us understand what is EPS and what is EPS Machine first.

1.What is EPS?

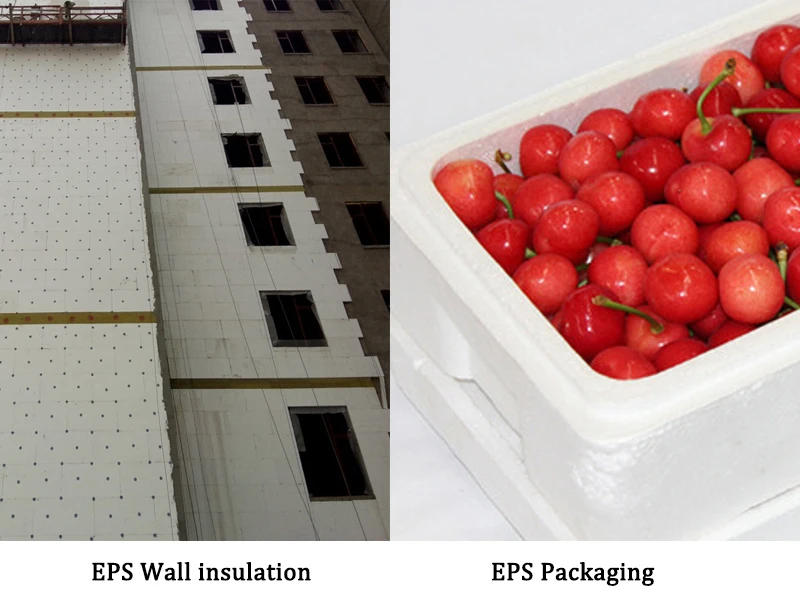

Expanded Polystyrene, EPS for short, is a rigid foam material with polystyrene beads containing a blowing agent and other additives for foaming. It is famous for its lightweight, good thermal insulation and versatile in strength. EPS is widely used in daily building insulation, food or industrial products packaging.

2.What is EPS Machine?

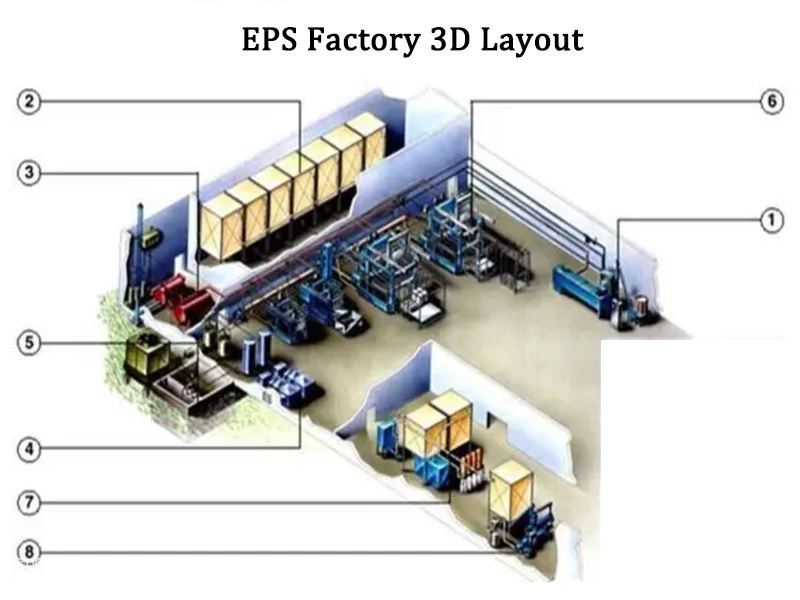

EPS machine is the special equipment to process the EPS products, normally includes EPS Pre-expander machine, EPS block moulding Machine, EPS shape moulding machine, EPS Cutting machine. Besides, lots of auxiliary equipment are needed for EPS project, like steam boiler, steam tank, air compressor, air tank, EPS silos, etc. Steam boiler provide heat energy for pre-expansion and air compressor provides automation air source for factory. (Picture from Kurtz)

2.1 EPS Pre-expander Machine

2.2 EPS Silo

2.3 Steam boiler

2.4 Compressed air station

2.5 Water cooling system

2.6 EPS Block Moulding Machine

2.7 EPS Crusher Machine

2.8 EPS Mixing Machine

3.How to make EPS block?

Simply, to produce EPS block, there is following stages: beads pre-expansion, EPS beads aging, EPS beads moulding, and Cutting.

3.1 Expansion by EPS Pre-expander Machine

The purpose of pre-expansion is to expand EPS beads to desired density. The EPS resins are fed to EPS Pre-expander Machine. The diameter of the beads increases with higher steam temperature, and get lower density. After discharge from the EPS pre-expander, the expanded beads will flow through a dryer to remove moisture, and then go to aging silo.

3.2 Aging in EPS Silo

After going into aging silo, the expanded beads are stored in EPS silo approx. 12~24 hours based on density, atmosphere temperature, etc. When beads go to silo in beginning, the beads inside pressure is higher than outside,during aging process, material cools and the left pentane inside goes out gradually. Finally the beads pressure get a balance between inside and outside.

3.3 Moulding by EPS Block Moulding Machine

The matured beads are taken into EPS Block Moulding Machine to form the EPS block. Moulding of EPS styrofoam may follow several sequences:

• Fill the EPS Block molding machine with expanded beads

• Heat the EPS Block mould by steam

• Cool the EPS beads by air or EPS Vacuum cooling system.

• Eject the finished block from the mold cavity.

Cooling of the foam part via vacuum allows the foam to stiffen and reduce its internal pressure.

3.4 Cutting by EPS Cutting Machine

Additional finishing operations, such as hot-wire cutting, embossing, printing, laminating, etc., can be used to customize for final applications. Another approx. 12~ 24h is needed before cutting after cooling from EPS Block Moulding Machine. After this time, EPS block can be cut by EPS Cutting machine, it is used to cut EPS block into block sheets for insulation or various shapes for decorations.

3.5 EPS Recycling

The EPS is recyclable, the EPS product can be crushed into beads by EPS crusher machine and mix with fresh material. Or it can be melted and make it into photo frame, comb, etc.

Post time: 05-22-2024