Horizontal EPS Block Machine

EPS Block Machine Introduction

The horizontal EPS Block Machine starts from China, it doesn’t need very high workshop. Now we add automatic block ejection system and weight system, to get more automation and helps to save labor cost.

The EPS Block Machine forms the EPS beads together into a block. There are following several sequences to produce the EPS Block:

• Fill the expanded EPS beads into EPS Block Machine though feeding device.

• Heat the EPS Block Machine by steam

• Cool the beads in mould by air or EPS Vacuum cooling system.

• Eject the finished block from the mold cavity.

A. EPS Block Machine Body

•This Expandable Polystyrene Block Moulding Machine is designed in horizontal type with only one side opening, to ensure the less steam leakage and keep enough vacuum during cooling.

•The body is welded construction. The inner walls are aluminum plate with slots, 5mm thickness.

•The machine is made with fix walls, according to the demand we can also offer adjustable walls.

•Block fusion quality is monitored by foam pressure sensor.

•The EPS Block Machine insulation (aluminum silicate fiber) is optional.

B. Fill Silo for Block Mould

Filling silo is on the top of EPS Block Moulding Machine, and material level is controlled by level sensors automatically (optional). The system will stop the machine when there is not sufficient material available in the silo.

C. Steaming System

In each process steps the steam pressure is regulated with main steam valve and individual steam regulating valves on each side. Twice cross heating technology designed in the program. Steam goes into block machine from 2 big sides and discharges from 4 small sides during first cross heating, and opposite step during second cross heating.

D. Control panel

Main cabinet, with security lock, is equipped with Delta/Siemens touch screen and PLC.

E. Block Ejection Weighting Unit

While process cycle completely, the front door opens and hydraulic driven ejectors will eject the EPS block to the front door. Afterwards the two air cylinders on top will push block to the weighting unit, after weighting, a tilter would upright the block from horizontal.

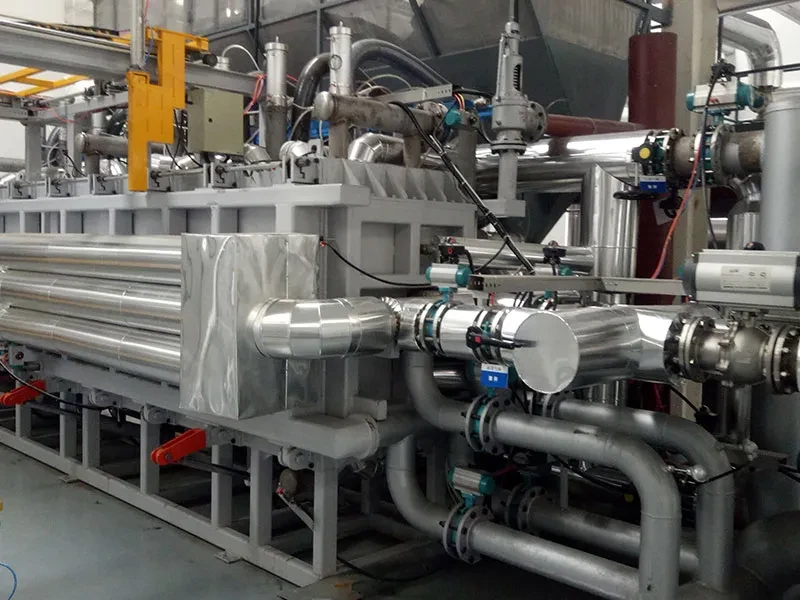

F. Vacuum system

Condenser tank ca. 1.5 m3 with water spraying and sieving units – individual vacuum tank ca. 10m3. Two vacuum pumps (11kw for each) used on machine. With the help of the vacuum, it helps to reduce the EPS cycle time and water content.

EPS Block Machine Specification

Model: SPB (2000/3000/4000/5000/6000) WZ

• Suitable for EPS block length: 2000-6000mm

• Suitable for EPS block Width: 1000-1200mm

• Suitable for EPS block Thickness: 1000-1200mm

• 12-15 blocks/hour @ density 15kg/m3

EPS Block Machine Features

• CE Certificate

• Multiple safety features

• Two operation mode can be selected: Step or Auto

• Weight unit, tilter and exit block conveyor is optional

• Homogenous Block density (+/- 3%)

• Low energy consumption and high output

• Automatic block ejection system, weighting and tilter system are optional

• EPS Block automatic conveyor system are optional.

• Machine color: Mould body RAL5012 Blue + piping system RAL3001 Red

EPS Block Conveyor System

The block conveyor system is controlled by touch screen & PLC, sensors and pneumatic, driven by motor and chains. Automatic drying system is available. It works between EPS block machine and continuous cutting line to increase plant automation, to reduce labor work strength and shorten drying time. While one line is full, the system would stop to feed this line and automatically switch to feed another line. While one line is empty, the system would stop discharge this line and switch to discharge another line.

EPS Block Moulding Machine Main parts

• Touch Screen + PLC: Delta/China

• Pressure gauge: YouLi/China

• Electronics: Schneider/France

• Aluminum plate: 2A12/China

• Butterfly valve: ABC valve/Singapore

• Ball valve: ABC valve/Singapore

• Angle valve: ESG/China

• Pneumatic parts: Airtec/China

• Vacuum pump: Yulong/China

• Photo sensor: Autonics/Korea