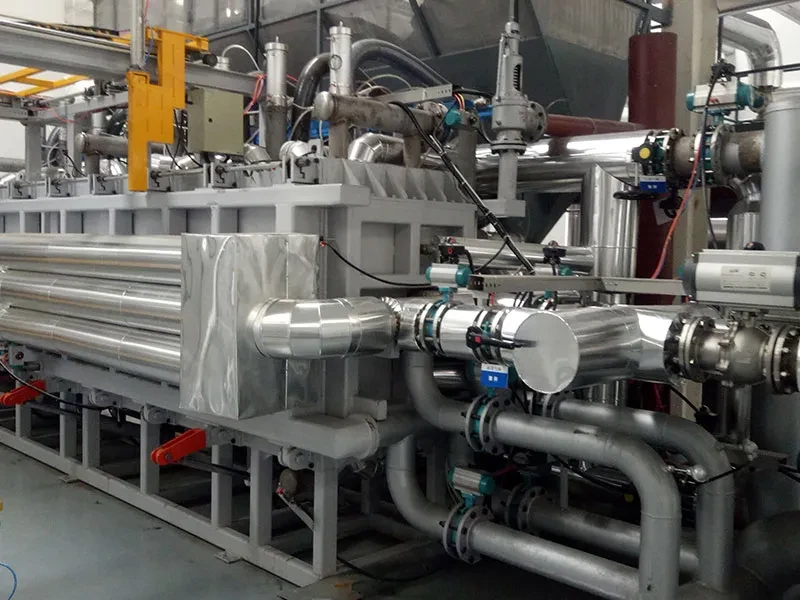

EPP Pre-expander Machine

EPP Pre-expander Machine Introduction

EPP is short for Expanded polypropylene, The purpose of EPP pre-expansion is to produce expandable polypropylene particles to the desired density. During pre-expansion, the EPP resins are fed to a vessel containing an agitator and controlled steam and air supplies, this vessel is called EPP Pre-expander. The diameter of the particles increases while the density of the resin decreases. After exiting from the pre-expander, the expanded beads will flow through a dryer to remove moisture, and then go to aging silo.

EPP Pre-expander Machine Specification

• Model: SPJY700

• Chamber diameter: 700mm

• Chamber height: 1000mm

• Output: 250~300kg/hr

EPP Pre-expander Machine Main parts

• Touch Screen + PLC: Mitsubishi/Japan

• Electronics: Schneider/France

• Pressure Reduction Valve: Yoshitake / Japan

• Pneumatic: Airtec/China

• Butterfly valve: Flowx/Italy

• Agitator motor: Guomao/China

• Blower: Shengtang/China

EPP Pre-expander Machine Features

• CE certificate

• Multiple safety features.

• Pressure Reduction Valve from Japan is used for steam control

• Frequency control of motor speed during expansion

• Fluid bed is equipped with heater to shorten aging time

• Automatic EPP Silo System is available to work with EPP Pre-expander together.

• Body: RAL5012 Blue + RAL3001 Red